Rewolucja w produkcji kasetonów – szybciej i precyzyjniej

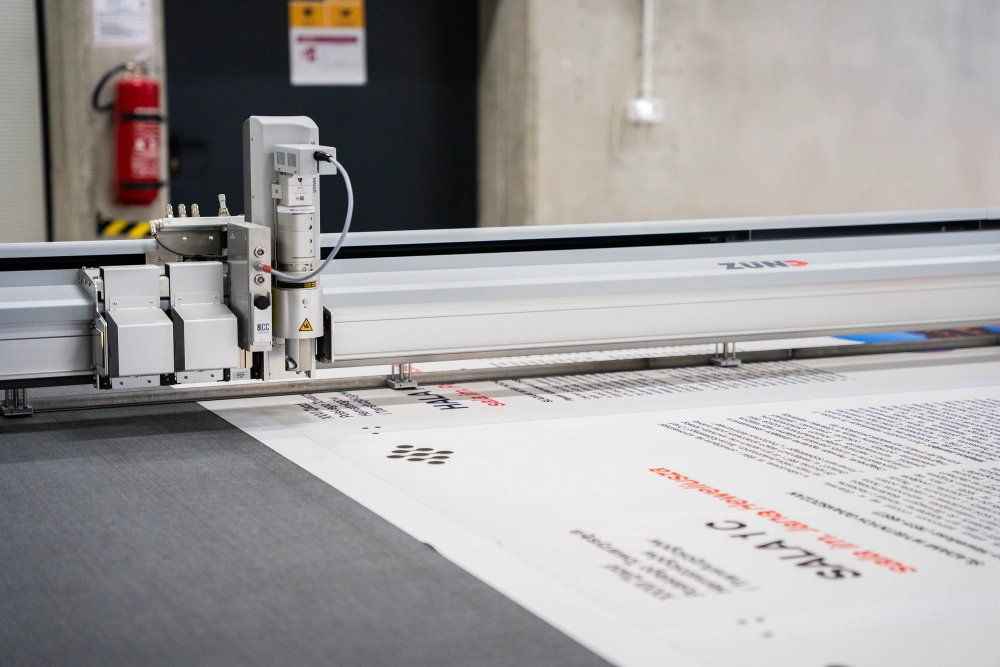

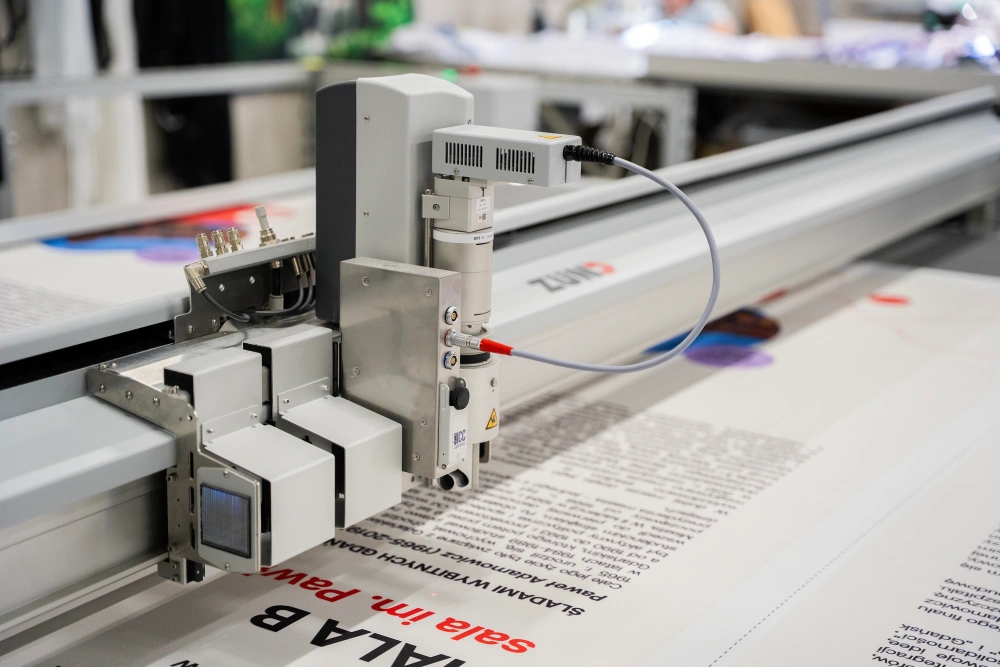

Nie lubisz nerwowej atmosfery przed targami? My też nie. Dlatego zamiast gonić czas, postanowiliśmy go wyprzedzić. Do naszego parku maszynowego wprowadziliśmy nowe urządzenie – ploter tnący ZUND. ZUND automatyzuje proces cięcia, zwiększa precyzję i minimalizuje ryzyko błędów. Zobacz, jak nowa maszyna może przyspieszyć realizację Twojego następnego zamówienia.

Automatyzacja, która przyspiesza produkcję

Ploter ZUND to prawdziwy game changer dla naszego działu produkcji. Maszyna automatyzuje proces wycinania wydruków zgodnie z wytycznymi. Wystarczy odpowiednio przygotowany plik, a cała magia dzieje się sama. ZUND rozpoznaje grafikę, dopasowuje ją do znaczników i rozpoczyna cięcie materiału z precyzją, której nie sposób uzyskać ręcznie.

Automatyzacja eliminuje błędy ludzkie, przyspiesza cały proces i pozwala produkować wielkoformatowe elementy w rekordowym tempie.

Szybszy proces to również mniejsze obciążenie dla zespołu. Operatorzy mogą skupić się na kontroli jakości i przygotowaniu kolejnych zleceń, a nie na żmudnym cięciu. Efekt? Produkcja płynie, a czas realizacji skraca się bez utraty jakości.

Jak działa nowy ploter tnący ZUND?

Precyzyjne cięcie zaczyna się od dobrze przygotowanego pliku – z wektorową linią cięcia i markerami graficznymi. Trafia on do maszyny wraz z kodem QR. Kiedy ZUND rozpoznaje rozwinięty z rolki, wydrukowany plik z odpowiednim kodem QR, automatycznie kojarzy oba elementy. Następnie ustawia grafikę względem markerów i precyzyjnie wycina zaprojektowany kształt. Dzięki temu do dalszej obróbki trafiają idealnie wycięte formatki, gotowe do montażu.

Ploter sprawdza się szczególnie przy kasetonach reklamowych oraz przy realizacjach o niestandardowych kształtach, gdzie ręczne cięcie wiązałoby się z ryzykiem niedokładności i dłuższym czasem pracy.

Co to oznacza dla naszych klientów? Jeszcze szybsza realizacja zamówień kasetonów reklamowych

Nowa maszyna to nie tylko inwestycja w technologię, ale przede wszystkim – w komfort klientów. Dzięki ZUND-owi skróciliśmy czas produkcji kasetonów i innych systemów wielkoformatowych. Oznacza to, że możemy przyjmować więcej zleceń i realizować je w krótszym terminie.

Więc jeśli Twój event zbliża się wielkimi krokami, a projekt jest jeszcze w fazie ustaleń – spokojnie. ZUND zdąży. Dzięki automatyzacji cięcia jesteśmy w stanie dostarczyć produkty szybciej niż kiedykolwiek, zachowując przy tym pełną jakość i zgodność z projektem. To duże ułatwienie – zwłaszcza dla agencji i klientów, którzy działają pod presją czasu.

Nowa technologia, ten sam standard jakości adsystem

W adsystem wciąż szukamy sposobów, by skracać czas realizacji, zachowując standard jakości, który od lat rozpoznają klienci z całej Europy. Każda inwestycja w naszym parku maszynowym ma jeden cel – dać i nam, i klientom większą pewność, że wszystko pójdzie zgodnie z planem.

Teraz możemy z czystym sumieniem powiedzieć: jesteśmy gotowi nawet na najbardziej napięte terminy.