Jak przygotować pliki pasowane? Poradnik krok po kroku

Planujesz ekspozycję złożoną z kilku elementów danego systemu, ale z jedną wspólną grafiką? Sprawdź, jak poprawnie przygotować pliki pasowane, aby uniknąć przesunięć i poprawek przed drukiem.

Kiedy i po co stosować pliki pasowane?

Pliki pasowane należy przygotować zawsze wtedy, gdy chcesz połączyć kilka prostokątnych elementów w jedną grafikę. Najczęściej chodzi o ramy tekstylne albo kasetony LED, ustawione obok siebie. Dzięki pasowaniu możesz mieć pewność, że całość będzie wyglądać jak jeden obraz, a nie kilka osobnych paneli.

Aby przygotować pliki pasowane, projekt należy podzielić na kilka plików. Każdy z nich powinien zawierać fragment grafiki z poprzedniego. Ten powtarzający się fragment to tzw. obszar wspólny, który pozwala zachować ciągłość obrazu.

Dlaczego to takie ważne? Między systemami zawsze pojawiają się drobne przerwy i przesunięcia wynikające z obszywania kedrem, krojenia, grubości profili czy samego montażu. Dodatkowo materiał potrafi się minimalnie skurczyć, a część grafiki jest przeznaczona na obszary techniczne. Gdy pliki są przygotowane „na styk”, linie i wzory łatwo się rozjeżdżają, a boczne krawędzie zawinięte do środka ram i obszyte kedrem, przełamują kontynuację obrazu. Dzięki obszarowi wspólnemu grafika układa się w spójną całość – przechodzi płynnie z jednej ramy na drugą i wygląda dokładnie tak, jak zakładał projekt.

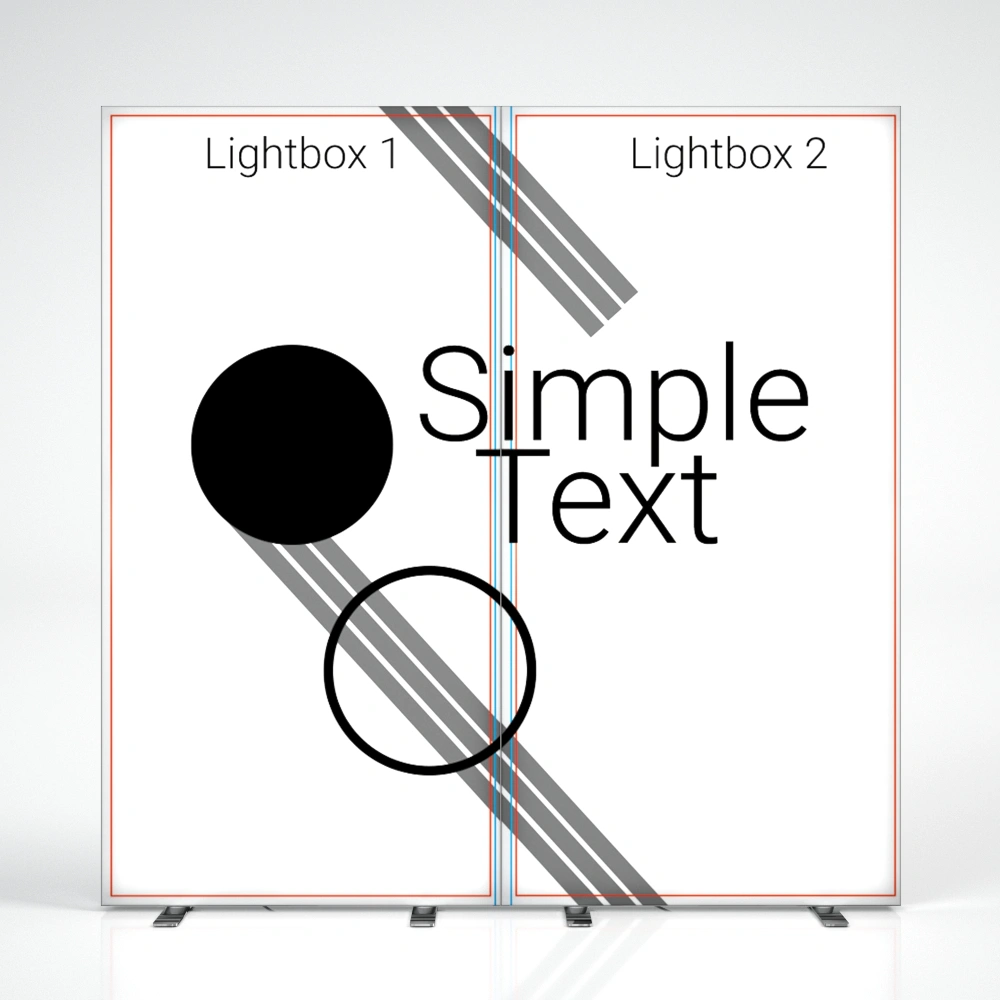

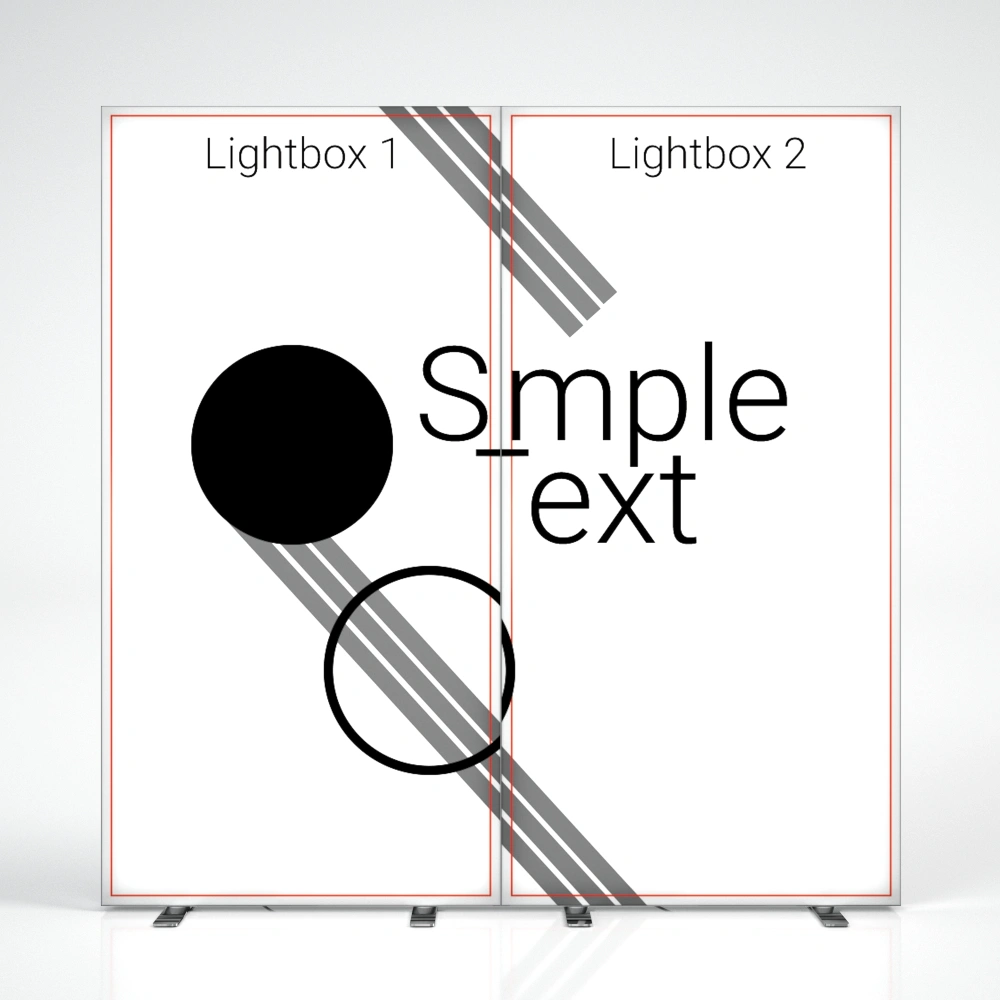

Dobrze

Źle

Jak przygotować pliki pasowane?

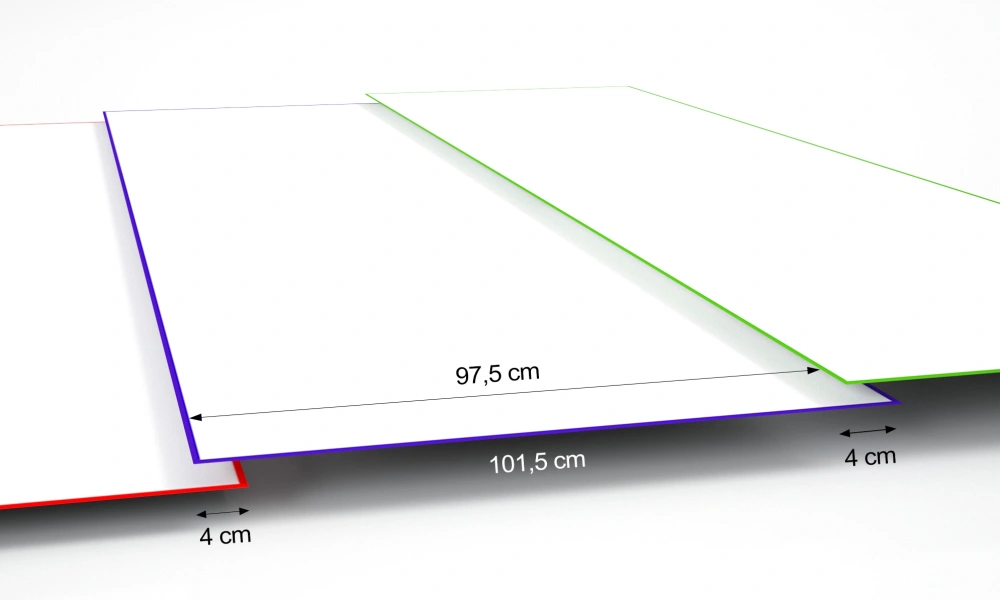

Zasada przygotowywania plików pasowanych jest prosta: każdy kolejny plik powinien zawierać 4 cm* obrazu z poprzedniego, aby zachować ciągłość grafiki. Poniżej znajdziesz schemat przygotowany na bazie wytycznych do wydruku 100×250 cm:

Jak przygotować pliki pasowane w praktyce? Zapoznaj się z krótką instrukcją, przygotowaną przez nasz zespół graficzny.

*Uwaga!

W przypadku systemów SEGO obszar wspólny wynosi 3 cm. To wyjątek od reguły.

Podsumowanie

Przygotowanie plików pasowanych może brzmieć skomplikowanie, ale w praktyce sprowadza się do kilku prostych zasad. Zawsze pracuj na wytycznych pobranych ze strony, pilnuj wymiarów i zostawiaj obszar wspólny – 4 cm (albo 3 cm w przypadku systemu SEGO) między kolejnymi plikami. Dzięki temu grafika płynnie przejdzie przez wszystkie systemy, bez przerw i przesunięć.

Jeśli zastosujesz się do tego schematu, Twoja ekspozycja będzie w pełni zgodna z projektem, a dodatkowo – unikniesz zbędnych poprawek i stresu tuż przed drukiem.